Why Us

Learn what sets us apart from our competition!

Passion for Quality, Innovation and Safety

Whether large or small, we treat each adventure project with the same level of care and attention. Of course your zip line needs to be beautiful, well-built, and safe. We go further. We work hard to understand your unique needs and vision. Armed with these insights (and 100+ years of combined industry experience), we’ll guide you through your project from start to finish.

To deliver on this promise, we offer a wide range of services to help with any or all project phases. From a straightforward single zip line to an entire zip line park, we can help you plan, design, construct and install your project – on time, and on budget. We get your adventure business up and running quickly, with minimal headaches and maximum satisfaction. Zipline Solutions can even assist with marketing strategies, guidelines for profitability, safety inspections, site planning and staff training.

Company Advantages

- Complete Design Build Services

- International Installation

- Project Management

- Widest Range Of Products and Services

- Computerized CNC

- Civil, Structural, Geotechnical, Ride Engineering Services

- Highest Quality Componentry

- 3D Concept Development

- Turnkey Solutions

- Steel / Wood Fabrication

- Specialization In Large-Scale Construction

- Ongoing Inspections

- Experienced Team

- In-House Manufacturing

Services

Site Planning

The first step to ensuring the ongoing success of a project is a visit. We’ll send someone out to assess the site, evaluate possible line and tower locations, and arrange surveying of exact elevations. With this data, we can develop a layout and formal site plan (if desired).

Design

Beginning with initial sketches and ending with exact 3D models of each cable, beam, and bolt, our design team takes care of bringing your vision to life. Unlike some of our competitors, we can handle the entirety of design (towers included).

Engineering

Our geo-technical, structural and ride engineers ensure the math checks out. From the soil composition to the load distribution to the dynamic rider envelope, we understand and orchestrate the myriad factors that make things work.

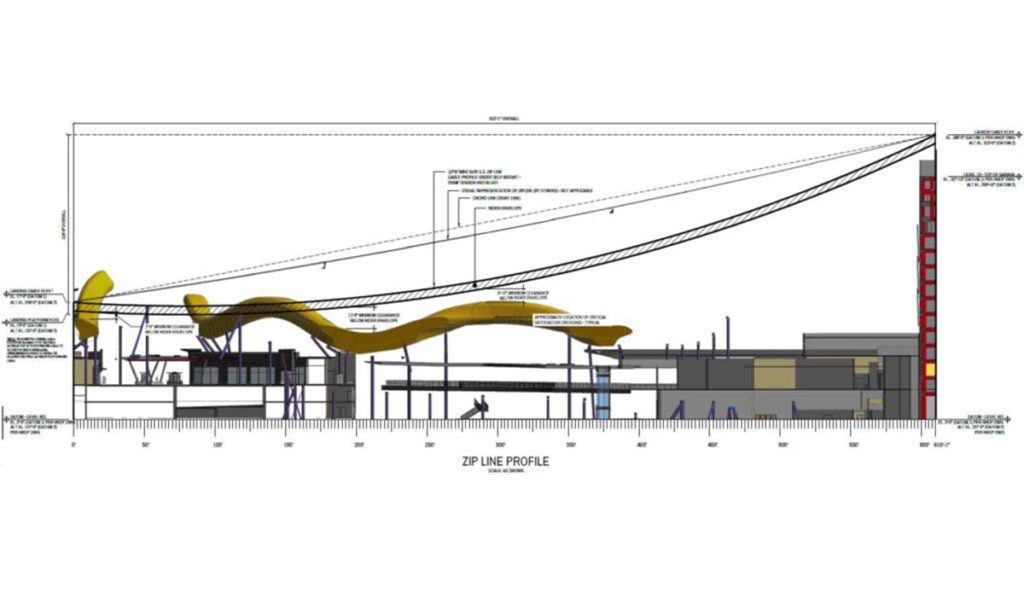

Cable Profile

In order to determine the ultimate profile of your zipline, we factor in the topography of the landscape, any clearance issues (e.g. buildings, etc.), actual line tension, reaction loads, sag, and finally, the launch and landing heights.

Fabrication

With in-house capabilities like CNC machining, laser cutting, metal fabrication, carpentry, and paint, we lay hands on every aspect of your project. By fabricating everything ourselves, we can guarantee a level of quality that others simply can’t.

Installation

Our team of builders are trained in every facet of zip line install. Each has years of experience, a fact immediately apparent when you see them in their element. They make sure every nut and bolt is as it ought to be.

Staff Training

In addition to providing an operational training manual, we always conduct hands-on training with your staff. Depending on the size and nature of your course, this usually lasts three to four days, covering every aspect of safe and efficient operation.

Inspections

Our installers inspect every facet of your project before leaving the site. But we don’t stop there. Based on the throughput of your course, it’s advisable to conduct a technical inspection every six months to a year. We stay with you, offering ongoing support on this front to ensure all hardware and the line itself exceed all safety standards, at all times.

Project Management

We believe a properly managed project leads to better outcomes. To this end, we empower the appropriate person to oversee all aspects of planning, production, and install, thereby maintaining a smooth pace of progress throughout.

WANT TO GET STARTED?

WE’D LOVE TO HEAR FROM YOU!